AN OVERVIEW OF AUTOMATIC GREASE SYSTEMS

Greetings,

After nearly 20 years in this industry, I’ve seen first-hand why automatic greasing systems are so important. I’ve worked with machinery and plants in all sorts of conditions whether it’s out in the fields, on construction sites, or in transport depots and consistent lubrication is key. Without it, machines wear down faster, break down more often, and cost a fortune in repairs. That’s why I’m such a strong advocate for automatic grease systems. They take the guesswork out of the equation and ensure your gear is always ready to perform at its best.

One common question I'm asked is "how does it work?" so here is a basic breakdown.

Automatic Grease Systems

Central Reservoir

Let me start with the central reservoir, the heart of the whole system. It’s where the grease is stored, whether you call it a grease cartridge, container or a reservoir. Over the years, I’ve seen systems with both refillable reservoirs and replaceable cartridges, and choosing the right one really depends on the specific needs of your machinery. But one thing’s for sure, when the system’s designed right, you’ll have enough grease to keep everything running smoothly for long stretches of time without worrying about constant refills.

Pump Mechanism

The pump plays a crucial role in this setup. Its primary function is to transport the grease from the reservoir to the areas where it is most needed. Depending on the system, it could be an electric pump or a pneumatic one that operates on compressed air, which is ideal for situations where electricity is not viable. I have hands-on experience with different types, including single line, dual line, and progressive systems. Matching the right pump and configuration to the specific job at hand is important.

Distribution Lines

Once the pump kicks in, the grease moves through the distribution lines. These lines are made from tough materials: steel, reinforced rubber, or nylon that can handle whatever environment they’re working in. Whether it’s heat, pressure, or exposure to harsh chemicals, these lines are built to last.

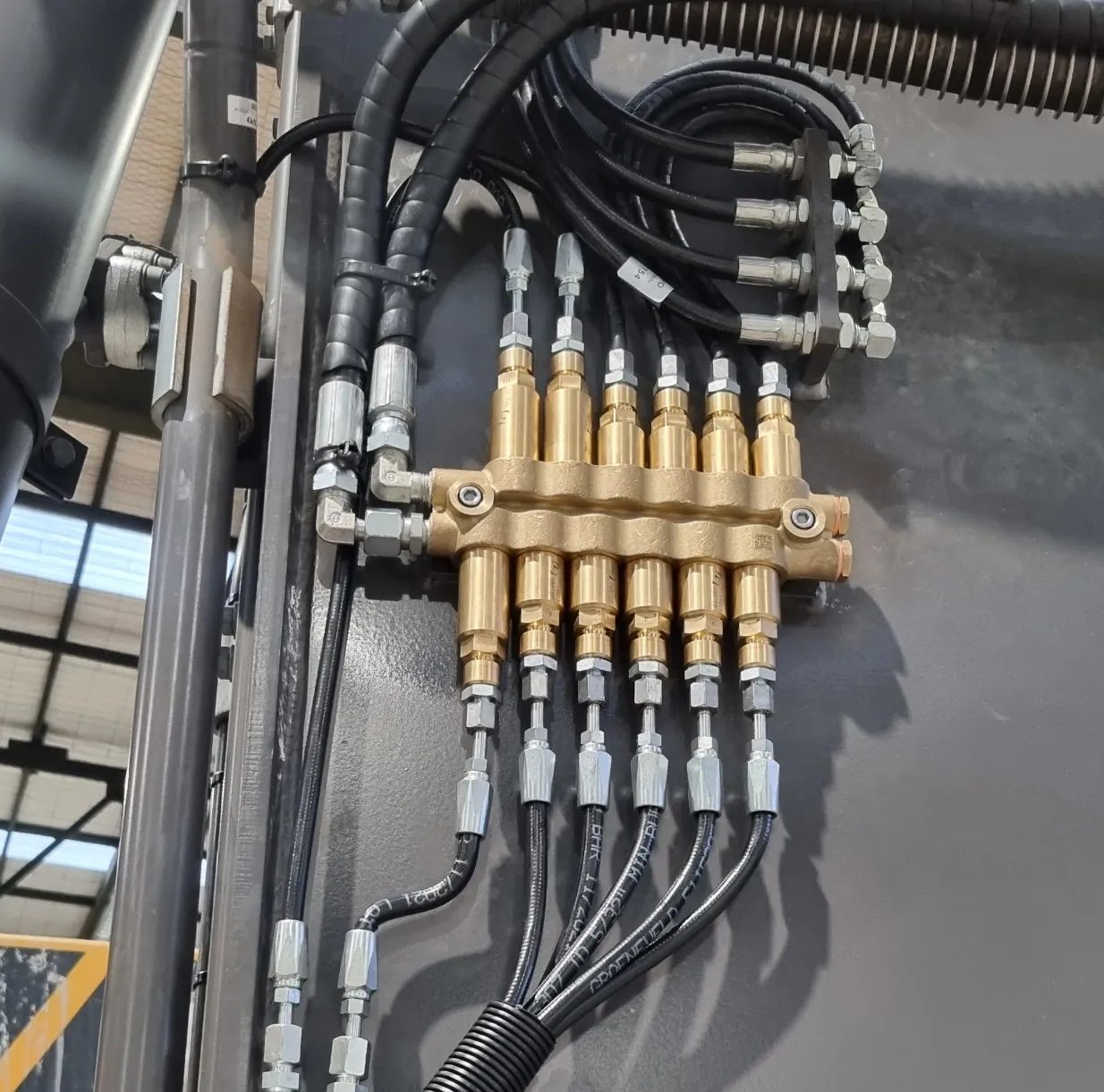

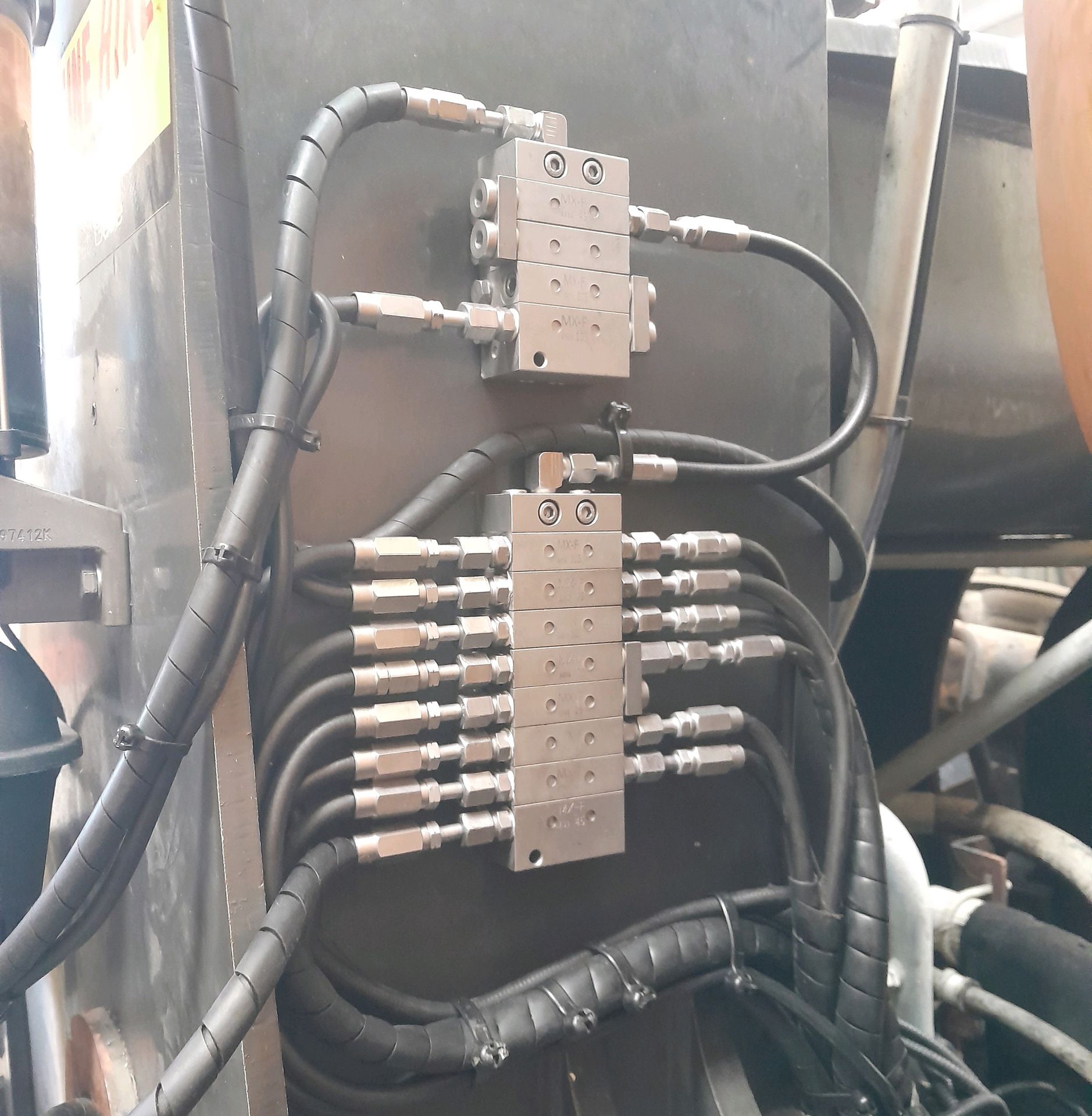

Grease Injectors or Distributors

Grease injectors or distributors are strategically placed along the system to ensure that every lubrication point gets exactly the right amount of grease.

Types of distributors.

Single-Point Lubricators (like the BEKA ONE): They’re great for machines with just one critical lubrication point.

Parallel Distributor Systems (like the Groeneveld Twin or Single Line): These can handle multiple points at once, making them ideal for larger equipment.

Progressive Block Systems (like BEKA Zepto, Pico, or EP-1): These distribute grease in sequence, ensuring that each point gets its turn.

Timing and Control

I’ve come to appreciate the brains behind these systems, the timing and control unit. Whether it’s a pneumatic timer or a fully programmable electronic controller, this component keeps everything in sync. It decides when and how much grease is needed, based on how hard the machine is working. I’ve seen systems tailored for all kinds of machines, adjusting the lubrication intervals to fit the load, speed, and environment.

Feedback Mechanism

To make sure everything’s running as it should, I can’t tell you how many times a simple sensor or pressure switch has saved the day by alerting me to an issue before it became a major problem. Sensors can monitor everything from grease flow to pressure and temperature, and low-level indicators let you know when it’s time to top up the reservoir. It’s like having a second set of eyes on your equipment 24/7.

Watch the Groeneveld Twin video showing how the system works on an earthmoving machine.

Why I Believe in Automatic Greasing Systems

I've been working with grease systems for nearly two decades and I’ve seen the benefits of automatic greasing systems up close. They keep everything lubricated exactly when it’s needed, which means fewer breakdowns and longer-lasting machinery. They save time, reduce labour costs, grease consumption and eliminate the guesswork involved in manual greasing. Plus, they help prevent human error, which I’ve seen lead to costly repairs more times than I can count. We regularly see customers achieve up to and above 3 times the life of components over manual greasing. Futhermore they contribute to a sustainable environment.

At the end of the day, automatic greasing systems make sure your equipment is always ready to go. And in my experience, that’s the key to getting the most out of your gear while keeping costs down and efficiency up. For anyone running serious machinery, these systems are a must-have.

Thank you for your time, feel free to reach out if you have any questions.

Jono.

Don't have a login? Email us to get access to your trade prices and more! Contact us now to get started.

An Overview of Automatic Grease Systems