ABOUT THE

GROENEVELD TWIN SYSTEM

For larger machines operating in demanding conditions, the Groeneveld Twin stands out with its unique product features. The system operates at low pressure, ensuring the grease's quality and structure are maintained.

Its dual-line system, equipped with patented metering units, guarantees optimal lubrication for all lubrication points. This precision is maintained even in extreme temperatures and over long distances between the pump and lubrication points.

Moreover, the system can be easily expanded to accommodate additional equipment pieces, making it ideal for large machines like wheel loaders, dump trucks, excavators, graders and mobile & fixed plant.

- Grease output and grease delivery independent of ambient temperature and grease viscosity

- Due to the relatively low work pressure, the quality of the grease is preserved

- Modern pump with real-time clock, memory, CAN-Bus connection and follower plate

- High quality metering units and distribution blocks

- Comes with in-cab display

- Available with reservoir volumes ranging from 2 to 200 litres

- Easy to program, install and extend

- The filling coupling with filter prevents contamination during filling

- Easily extended to grippers, excavation buckets and other equipment pieces through quick couplers

- Suitable for biodegradable grease

Watch video: How a Groeneveld Twin system works

Download PDF: General Manual and Specifications

Error code quick reference: Click here

OVERVIEW OF THE

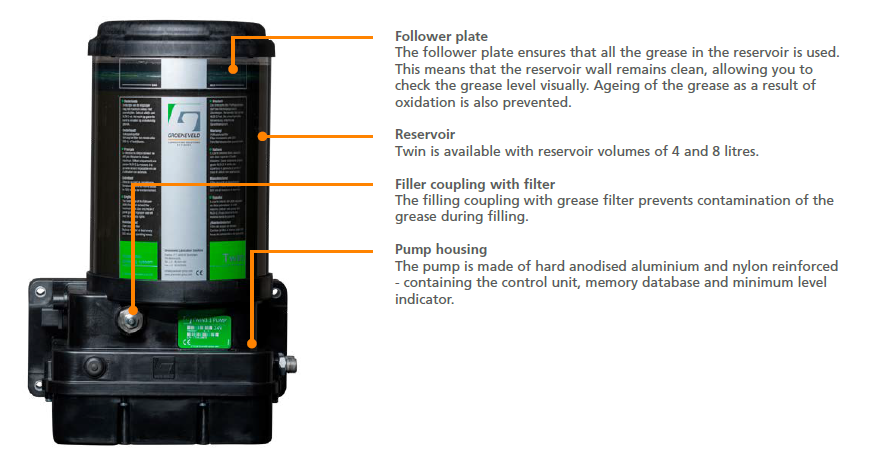

GROENEVELD TWIN PUMP

Working Principles

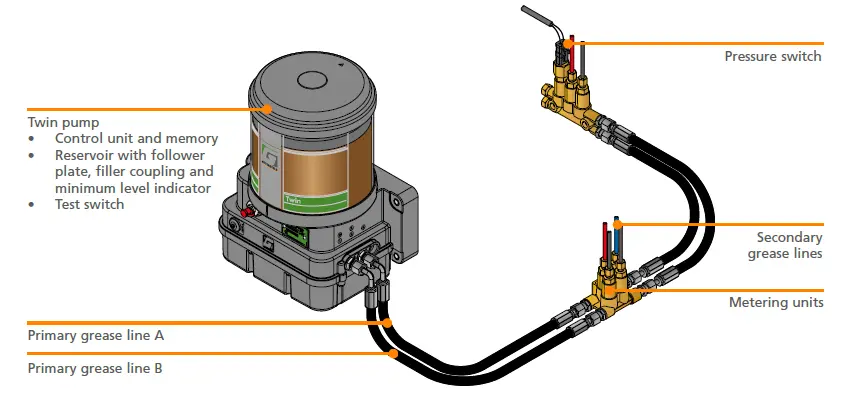

A Twin system consists of a pump with a grease reservoir, a main line network to the distribution blocks with metering units and a secondary line network to the lubrication points. The grease is pumped into the distribution blocks via a double main line network. The metering units supply the exact amount of grease needed to each of the lubricant points. The pump switches off once the pressure in all metering units is at least 100 bar. As a result, the right amount of grease is consistently provided to each lubrication point, independent of the counter-pressure, temperature or viscosity of the grease.

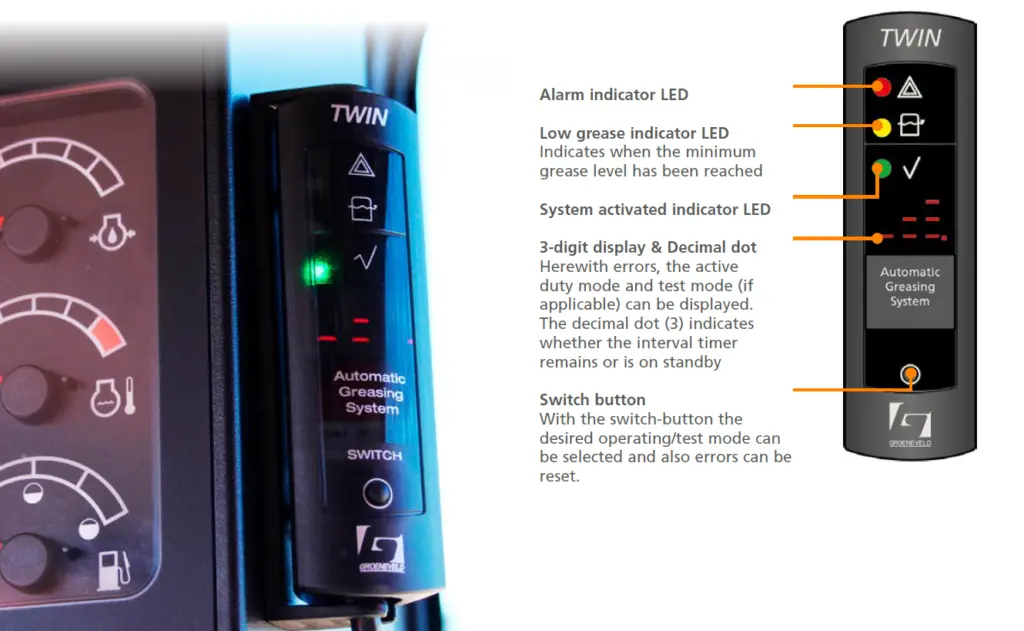

In-Cab Display

In order to check the status of the system, the driver or operator does not have to leave the cabin. The in-cab display will show system messages in the cabin. This will allow an easy and fast diagnosis of the system, as well as remote assistance.

Technical Information Twin Pump

Pump Type | Electric piston pump |

No. of outputs | 1 |

Maximum number of lubrication points | 200* |

Grease delivery Twin | 12 cc/min |

Grease delivery Twin XL | 20 cc/min |

Grease delivery Twin Barrel Pump | 60 cc/min |

Maximum operating pressure | 250 bar (3625 psi) |

Grease class | NLGI-2 |

Temperature range | -20 up to +70 C (-4 up to 158 F) |

Supply Voltage | 12 or 24 Vdc |

Protection class | IP67 (for pump unit) |

Regulations / EMC | Automotive directive 72/245/EC, as last amended by directive 2006/28/EC. Earth Moving Machinery standard: ISO 13766 |

*Depending on system resistance, grease delivery and tubing length.

Technical Information Twin Display

Supply voltage | 9 - 32 Vdc |

Maximum operating current | 220 mA |

Temperature range | -25 up to +70 C (-13 up to 158 F) |

Protection class | IP54 |

Regulations / EMC | Off road ISO 13766-2006 Road transport 2004/104/EC Industrial equipment 2004/108/EC |

AN OVERVIEW

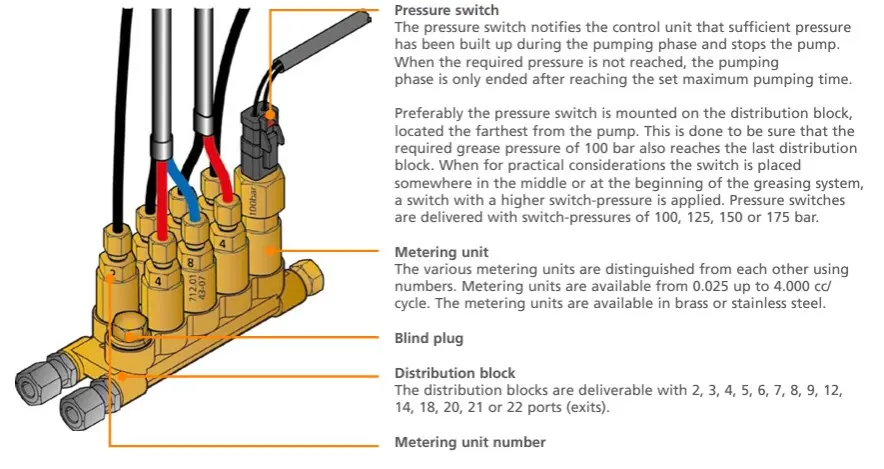

DUAL LINE DISTRIBUTION BLOCKS AND METERING UNITS

There is a wide range of distribution blocks and metering units available for the Groeneveld-BEKA dual line systems. By carefully selecting the type of metering unit, each grease point can receive the appropriate amount of grease per greasing cycle, as they all have varying grease outputs. Dual line distribution blocks are created by combining a distribution block with different metering units. Any unused ports on the distribution block can be sealed with a blind plug. Additionally, a pressure switch can be installed in one of the ports. The metering units deliver the lubricant under pressure through secondary lines directly to the lubrication points. A distribution block with metering units forms a sealed structure, allowing it to be installed in damp or dirty environments without issue. Both distribution blocks and metering units are offered in brass and stainless steel by request, with brass being the standard material.

Types of metering units

The metering units are provided with different grease delivery rates and are identified by numbers. If the maximum dosing rate does not supply enough grease to a grease point, it is possible to connect multiple metering units together.

Metering Unit | CC per Cycle |

0 | 0.025cc |

1 | 0.050cc |

2 | 0.100cc |

3 | 0.150cc |

4 | 0.200cc |

5 | 0.250cc |

6 | 0.300cc |

7 | 0.350cc |

8 | 0.400cc |

8.5 | 0.700cc |

9 | 1.000cc |

10 | 2.000cc |

11 | 4.000cc |